0 引言

1 纤维素生产末端废水零排放项目MVR蒸发器设计

1.1 工程应用案例设计条件

1.2 设计流程与管内外传热、流阻计算

Fig. 1 Design and calculation flow chart of three-dimensional deformation tube MVR evaporator图1 三维变形管MVR蒸发器设计计算流程图 |

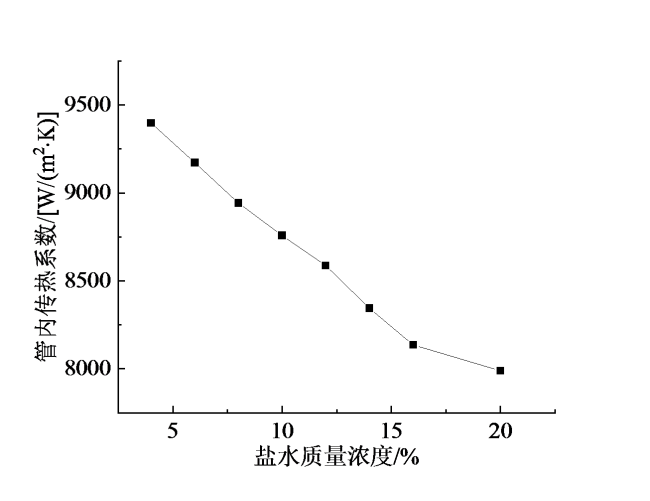

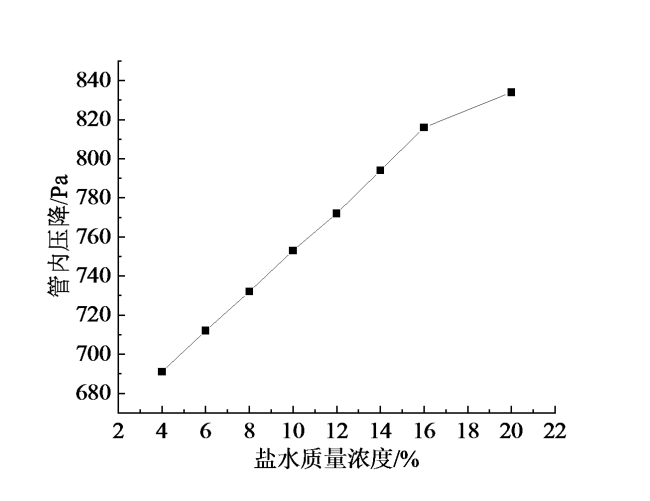

1.3 管内换热盐水浓度的影响修正

Fig. 2 Local grid diagram of 3D-deformation tube: (a) cross-section grid; (b) vertical grid图2 3D管局部网格示意图:(a)横截面网格;(b)纵向网格 |

Fig. 3 Variation of heat transfer coefficient inside the tube with brine concentration图3 管内传热系数随盐水浓度变化图 |

Fig. 4 Variation of fluid pressure drop with brine concentration图4 流体压降随盐水浓度变化图 |

1.4 设计计算结果与传统直圆管蒸发器的对比

Table 1 Comparison of optimized design parameters of 3D tube evaporator and traditional straight circular evaporator design parameters表1 3D管蒸发器优化设计参数与传统直圆管蒸发器设计参数对比 |

| 参数 | 直圆管蒸发器 | 3D管蒸发器 | 对比 |

|---|---|---|---|

| 废水循环流量/(m3/h) | 3 850 | 3 850 | |

| 废水处理量/(m3/h) | 17.36 | 17.36 | |

| 废水进口温度/℃ | 98.05 | 98.05 | |

| 废水出口温度/℃ | 99.8 | 99.8 | |

| 管内压力/kPa | 150(表压) | 150(表压) | |

| 管内允许压降/kPa | 35 | 35 | |

| 管内压降/kPa | 27.4 | 30.8 | +12.41% |

| 蒸汽流量/(t/h) | 14.35 | 14.35 | |

| 蒸汽温度/℃ | 110 | 110 | |

| 壳程压力/kPa | 143(绝对) | 143(绝对) | |

| 总换热量/kW | 8 889.1 | 8 889.1 | |

| 换热面积/m2 | 1 252.62 | 888.69 | -29.05% |

| 总传热系数/[W/(m2∙K)] | 837 | 1 188 | +41.93% |

| 裕量/% | 30.6% | 21.1% | |

| 流程 | 1/1 | 1/1 | |

| 换热管尺寸/mm | Φ 32 × 1.5 × 10 000 | Φ 32 × 1.5 × 8 000 A = 38,B = 22, P = 300 | |

| 筒体尺寸/mm | Φ 2 100 × 12 000 | Φ 1 900 × 10 000 | -31.78% |

| 换热管数目/根 | 1 246 | 1 105 | |

| 换热管材质 | 钛 | 钛 | |

| 筒体材质 | 304不锈钢 | 304不锈钢 |

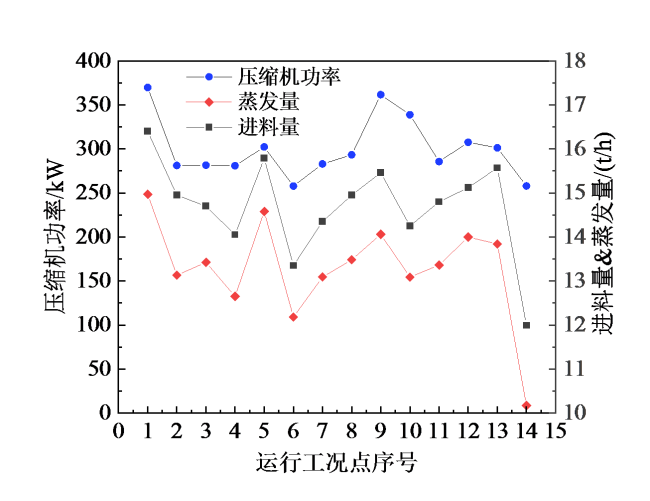

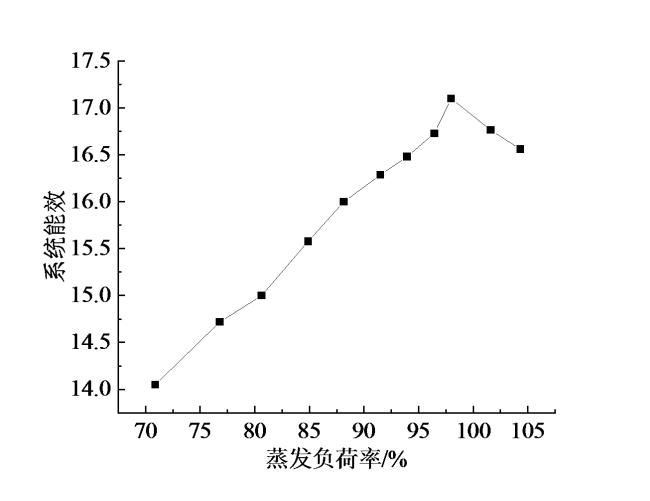

2 实际运行结果与分析

Fig. 5 Schematic diagram of the change of MVR compressor power with feed volume and evaporation volume during actual operation图5 实际运行时压缩机功率随进料量和蒸发量的变化示意图 |

Table 2 Comparison of comprehensive heat transfer performance and design conditions of actual operation of 3D tube MVR evaporator表2 3D管MVR蒸发器实际运行综合换热性能与设计工况对比 |

| 参数 | 设计值 | 实际监测值 | 对比 |

|---|---|---|---|

| 废水循环流量/(m3/h) | 3 850 | 3 997 | +3.80% |

| 新进废水量(常温)/(m3/h) | 17.36 | 14.95 | -13.90% |

| 循环倍率 | 221.8 | 267.4 | +20.60% |

| 废水进口温度/℃ | 98.05 | 96.53 | |

| 废水出口温度/℃ | 99.8 | 98.39 | |

| 压缩机进口压力/kPa | 81.31 | 60.94 | |

| 压缩机出口压力/kPa | 133.45 | 105.35 | |

| 压缩比 | 1.641 | 1.729 | |

| 压缩机耗电功率/kW | 465.21 | 300.21 | -35.47% |

| 循环水泵耗电功率/kW | 113.9 | 93.96 | -17.51% |

| MVR系统总耗电功率/kW | 706.23 | 521.29 | -26.19% |

| 蒸汽流量/(t/h) | 14.35 | 13.22 | -7.90% |

| 蒸汽温度/℃ | 110 | 103.14 | |

| 换热温差/℃ | 11.08 | 5.63 | -49.20% |

| 出料量/(m3/h) | 3.01 | 1.98 | -34.20% |

| 总换热量/kW | 10 753.5 | 8 265.1 | -23.10% |

| 总传热系数/[W/(m2∙K)] | 1 188 | 1 586 | +33.50% |

| 系统能效 | 15.23① | 15.86 | +4.13% |

①设计系统能效为设计工况条件下的预测值。 |

Fig. 6 The trend of MVR system energy efficiency with evaporation load in actual operation图6 实际运行时MVR系统能效随蒸发负荷率的变化趋势 |