0 引言

1 合成气一步法制低碳烯烃工艺

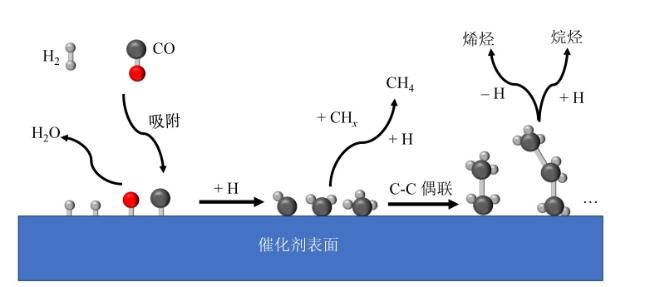

1.1 费托合成工艺

Fig. 1 Reaction mechanism of carbide in Fischer-Tropsch process图1 费托合成碳化物反应机制 |

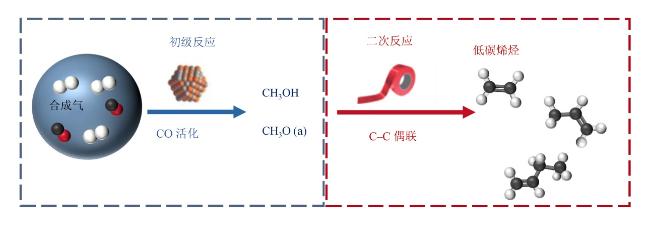

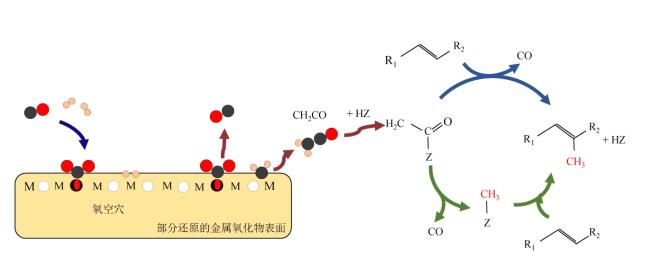

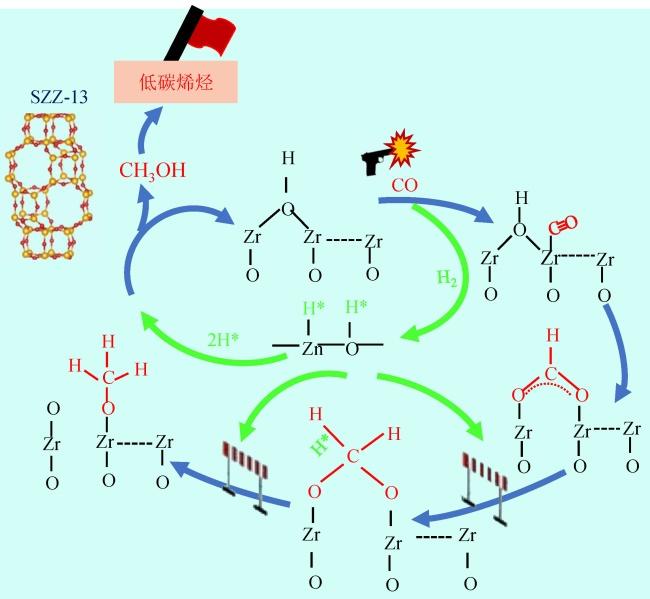

1.2 双功能催化工艺

2 合成气一步法制低碳烯烃催化剂研究进展

2.1 费托合成催化剂研究进展

Table 1 Iron based catalysts for FTS production of olefins表1 FTS生产烯烃的铁基催化剂 |

| 催化剂 | 温度/℃ | 压力/MPa | H2/CO | CO转化率/% | CO2选择性/% | CH4选择性/% | C2= ~ C4= 选择性/% | 参考文献 |

|---|---|---|---|---|---|---|---|---|

| Na-S-Fe/α-Al2O3 | 340 | 2.0 | 1.00 | 80.0 | 40.0 | 11.0 | 53.0 | [29] |

| Fe-Mn-K/CNTs | 270 | 2.0 | 1.00 | 22.7 | 36.1 | 28.8 | 50.3 | [15] |

| Na-S-Fe/CNF | 340 | 2.0 | 1.00 | 2.0 | 33.0 | 14.0 | 72.0 | [30] |

| FeMn/S80-E | 300 | 2.1 | 1.00 | 50.5 | 33.4 | 13.3 | 54.6 | [31] |

| MgFe-CO3-LDH | 300 | 2.0 | 2.00 | 29.9 | 19.4 | 24.1 | 42.7 | [32] |

| NaS-FeMnOx | 280 | 0.1 | 2.00 | 19.0 | 46.0 | 5.0 | 18.0 | [33] |

| Fe5C2/NC600 | 250 | 0.2 | 2.00 | 22.3 (±0.5) | 16.7 (±1.3) | 22.3 (±1.1) | 55.6 (±0.4) | [34] |

| FeMn | 325 | 1.0 | 3.50 | 93.2 | 21.5 | 22.5 | 19.9 | [35] |

| FeMnNa | 325 | 1.0 | 3.50 | 96.2 | 26.8 | 16.6 | 30.5 | |

| FeMnK | 325 | 1.0 | 3.50 | 95.0 | 32.4 | 12.6 | 27.7 | |

| Mn15Na32im | 320 | 1.5 | 3.00 | 97.2 | 31.9 | 12.4 | 33.0 | [36] |

| Fe/SiO2 | 300 | 2.0 | 2.00 | 23.0 | 13.2 | 28.5 | 10.1 | [37] |

| Fe-Cu/SiO2 | 300 | 2.0 | 2.00 | 33.9 | 15.9 | 20.8 | 15.2 | |

| Fe-K/SiO2 | 300 | 2.0 | 2.00 | 29.9 | 20.9 | 12.9 | 18.7 | |

| Fe-Cu-K/SiO2 | 300 | 2.0 | 2.00 | 34.3 | 22.7 | 14.0 | 18.1 | |

| K-Cu-Fe/γ-Al2O3 | 270 | 2.3 | 1.25 | 87.0 | 47.0 | 15.0 | 11.0 | [38] |

| K-Cu-Fe/mAl2O3-TiO2 | 270 | 2.3 | 1.25 | 86.0 | 43.0 | 11.0 | 12.0 | |

| K-Cu-Fe/mAl2O3 | 270 | 2.3 | 1.25 | 95.0 | 43.0 | 12.0 | 11.0 | |

| Fe-Mn-Li/CNTs | 300 | 1.0 | 1.00 | 14.2 | 40.3 | 23.3 | 48.4 | [39] |

| 15%Fe/AG (12h)-W(10) | 350 | 2.0 | 2.00 | 97.2 | 28.2 | 18.8 | 41.2 | [40] |

| Na-S-Fe/α-Al2O3 | 340 | 2.0 | 1.00 | 60.0 ~ 66.0 | 45.0 ~ 50.0 | <20.0 | 50.0 | [20] |

| Fe-Mn-V-K | 320 | 2.0 | 2.00 | 94.8 | 20.7 | 20.1 | 39.2 | [41] |

| Mn-FeN/CNT | 300 | 2.0 | 2.00 | 11.8 | 36.1 | 23.6 | 43.9 | [42] |

| FeMn@HZSM-5 | 280 | 1.0 | 2.00 | 78.5 | 28.3 | 18.7 | 41.4 | |

| FeMnK@H-S-1(0.20) | 280 | 0.5 | 1.90 | 13.9 | — | — | 50.6 | [43] |

Table 2 Cobalt based catalysts for FTS production of olefins表2 FTS生产烯烃的钴基催化剂 |

| 催化剂 | 温度/℃ | 压力/MPa | H2/CO | CO转化率/% | CO2选择性/% | CH4选择性/% | C2= ~ C4= 选择性/% | 参考文献 |

|---|---|---|---|---|---|---|---|---|

| Mn-Co/CNTs | 220 | 1.5 | 2.0 | 70.3 | 0.1 | 7.8 | 10.6 | [61] |

| Co-Zn/TiO2 | 240 | 0.1 | 2.0 | 65.2 | 1.5 | 9.3 | 46.5 | [62] |

| Co-Mn/TiO2 | 250 | 0.1 | 1.0 | 44.0 | 6.0 | 7.4 | 54.4 | [63] |

| Co-Mn | 250 | 0.1 | 2.0 | 31.8 | 47.3 | 5.0 | 60.0 | [46] |

| Co/AC | 220 | 3.0 | 2.0 | 47.5 | 0.7 | 22.9 | 14.7 | [64] |

| Co-Mn/AC | 220 | 3.0 | 2.0 | 40.5 | 1.8 | 8.6 | 41.4 | |

| Co/conv-HZSM-5 | 240 | 1.0 | 2.0 | 75.9 | 1.7 | 14.8 | 30.9 | [65] |

| Co/meso-HZSM-5 | 240 | 1.0 | 2.0 | 79.0 | 2.3 | 13.4 | 29.1 | |

| CoMnAl@6.6Si | 260 | 1.0 | 0.5 | 12.5 | 15.1 | 6.5 | 58.8 | [66] |

| Co/Mn/Na/S | 240 | 0.1 | 2.0 | 0.8 | — | 17.0 | 54.0 | [67] |

| Co/TiO | 220 | 2.0 | 2.0 | 10.0 | — | 16.9 | 32.3 | [68] |

| Ru-Co/TiO | 220 | 2.0 | 2.0 | 10.0 | — | 18.0 | 29.2 | |

| CoMnC-450 | 210 | 0.2 | 1.0 | 12.6 | 18.2 | 22.4 | 36.5 | [69] |

2.2 双功能催化剂研究进展

Table 3 Summary of bifunctional catalysts for olefin production using the OX-ZEO route表3 OX-ZEO路线生产烯烃双功能催化剂总结 |

| 催化剂 | 温度/℃ | 压力/MPa | H2/CO | CO转化率/% | CO2选择性/% | C2= ~ C4= 选择性/% | C20 ~ C40 选择性/% | C5+ 选择性/% | 参考文献 |

|---|---|---|---|---|---|---|---|---|---|

| ZnCrOx/SAPO-34 | 400 | 2.5 | 2.5 | 17.0 | 2.0 | 80.0 | 14.0 | 4.0 | [10] |

| Zn-ZrO2/SSZ-13 | 400 | 3.0 | 2.0 | 29.0 | <3.0 | 77.0 | 18.0 | — | [13] |

| ZnCrOx/AlPO-18 | 390 | 4.0 | 1.0 | 25.2 | <1.5 | 45.0 | 1.5 | 5.0 | [74] |

| MnOx/SAPO-34 | 400 | 2.5 | 2.5 | 7.3 | 1.4 | 80.0 | 14.5 | <5.0 | [70] |

| CoMn/Na-β | 250 | 0.1 | 1.0 | 6.8 | 25.0 | 48.8 | 8.6 | 17.6 | [78] |

| ZnAl2O4/SAPO-34 | 350 | 1.0 | 2.0 | 13.0 | — | 85.0 | — | — | [79] |

| ZnCrAlOx/SPM-X | 400 | 3.0 | 2.0 | 50.1 | 17.0 | 58.1 | — | — | [80] |

| ZnO-ZrO2/SAPO-34 | 400 | 2.0 | 1.0 | 7.0 | 4.0 | 69.0 | 25.0 | 2.0 | [81] |

| Zn1Cr1/S34-Dual(0.025)a | 400 | 2.0 | 2.0 | 39.9 | 44.4 | 76.1 | 11.4 | 9.5 | [82] |

| ZnO/SAPO-34 | 400 | 4.0 | 2.5 | 32.0 | 3.0 | 77.0 | 15.0 | 5.0 | [72] |

| ZnGaOx_NP/SAPO-34a | 400 | 4.0 | 2.5 | 49.5 | 41.1 | 75.6 | 16.9 | 5.8 | [83] |

| ZnCrOx/GeAPO-18a | 430 | 6.0 | 2.5 | 85.0 | — | 83.0 | 5.2 | — | [84] |

注:a代表产物选择性不包括CO2。 |