0 引言

1 电池系统台架液冷控制方法

1.1 电池系统低温加热试验方法

1.2 电池系统高温冷却试验方法

1.3 水冷机加热功率设定

Table 1 Temperature difference ΔT under different heating/cooling capacity P and coolant flow Q表1 不同加热/冷却功率P和流量Q条件下的进出水口温差ΔT |

| 流量Q / (L/min) | 进出水口温差 ΔT / K | |||||||

|---|---|---|---|---|---|---|---|---|

| P = -10 kW | P = -6 kW | P = -4 kW | P = -1.5 kW | P = -1 kW | P = 2 kW | P = 4 kW | P = 6 kW | |

| 2 | -90.9 | -54.5 | -36.4 | -22.7 | -9.1 | 18.2 | 36.4 | 54.5 |

| 4 | -45.5 | -27.3 | -18.2 | -11.4 | -4.5 | 9.1 | 18.2 | 27.3 |

| 6 | -30.3 | -18.2 | -12.1 | -7.6 | -3.0 | 6.1 | 12.1 | 18.2 |

| 8 | -22.7 | -13.6 | -9.1 | -5.7 | -2.3 | 4.5 | 9.1 | 13.6 |

| 10 | -18.2 | -10.9 | -7.3 | -4.5 | -1.8 | 3.6 | 7.3 | 10.9 |

| 12 | -15.2 | -9.1 | -6.1 | -3.8 | -1.5 | 3.0 | 6.1 | 9.1 |

注:冷却介质为水和乙二醇,混合体积比为1:1;在50℃下比热容为2.47 kJ/(kg∙K)。 |

1.4 电池系统台架液冷控制方法优化

2 结果与讨论

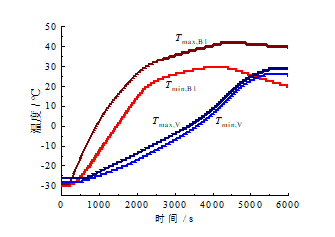

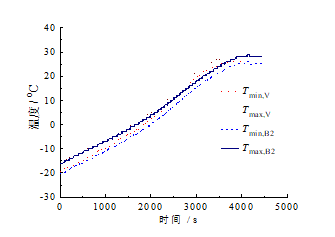

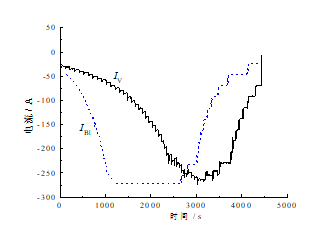

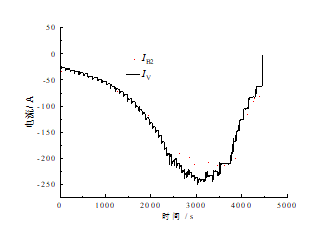

2.1 -20℃低温快充

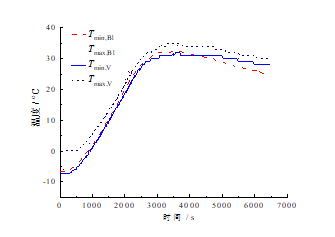

Fig. 1 Battery temperature change of vehicle and traditional bench at -20oC fast charge test图1 -20℃下整车与传统台架水冷的快充温度变化 |

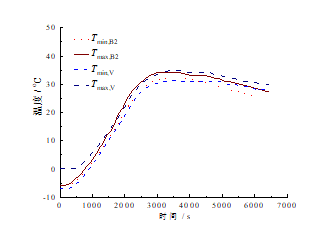

Fig. 2 Battery temperature change of vehicle and optimized bench at -20oC fast charge test图2 -20℃下整车与台架水冷优化后的快充温度变化 |

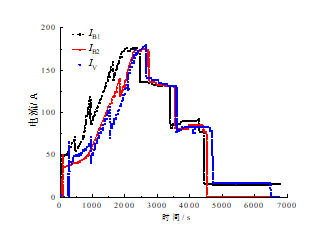

Fig. 3 Current changes of vehicle and traditional bench at -20oC fast charge test图3 -20℃下整车与传统台架水冷的快充电流变化 |

Fig. 4 Current changes of vehicle and optimized bench at -20oC fast charge test图4 -20℃下整车与台架水冷优化后的快充电流变化 |

2.2 -10℃低温快充

Fig. 5 Battery temperature change of vehicle and traditional bench at -10oC fast charge test图5 -10℃下整车与传统台架水冷的快充温度变化 |

Fig. 6 Battery temperature change of vehicle and optimized bench at -10oC fast charge test图6 -10℃下整车与台架水冷优化后的快充温度变化 |

Fig. 7 Current change of vehicle and bench at -10oC fast charge test图7 -10℃下整车与台架水冷的低温快充的电流变化 |

2.3 -20℃低温慢充

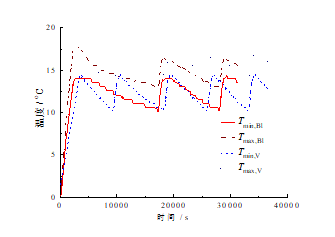

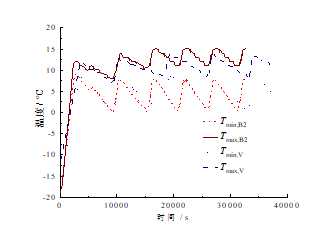

Fig. 8 Battery temperature change of vehicle and traditional bench at -20oC slow charge test图8 -20℃下整车与传统台架水冷的慢充温度变化 |

Fig. 9 Battery temperature change of vehicle and optimized bench at -20oC slow charge test图9 -20℃下整车与台架水冷优化后的慢充温度变化 |

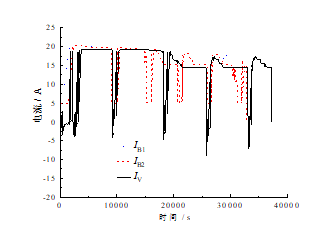

Fig. 10 Current change of vehicle and bench at -20oC slow charge test图10 -20℃下整车与台架水冷优化前后的慢充电流变化 |