0 引言

1 实验部分

1.1 试验原材料

1.2 测试方法及仪器

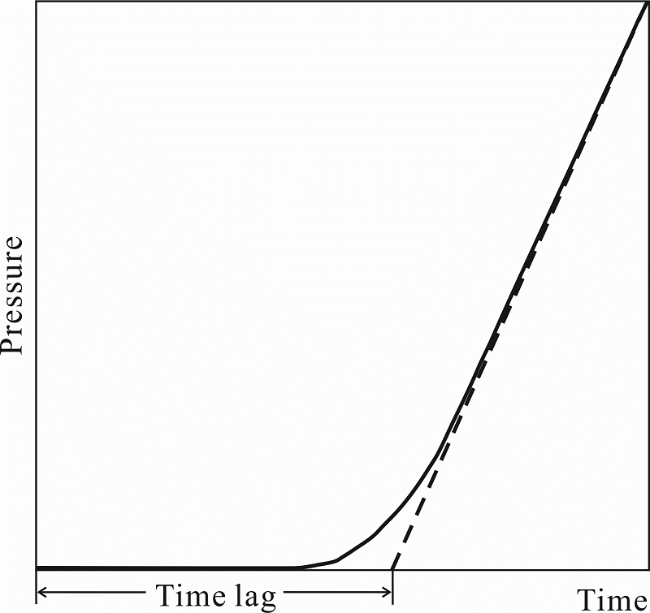

Fig. 1 Schematic diagram of time lag calculation method图1 滞后时间计算方法示意图 |

2 结果与讨论

2.1 结晶度测试

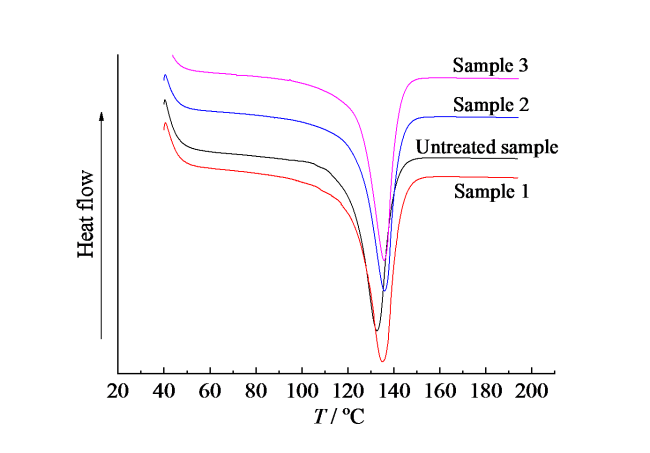

Fig. 2 DSC melting curves with different cooling processes图2 不同降温过程内胆试样的DSC熔融曲线 |

Table 1 Crystallinity of HDPE with different cooling processes表1 不同降温方式HDPE的结晶度 |

| Sample | Crystallization melting enthalpy / (J/g) | Crystallinity / % |

|---|---|---|

| Untreated | 167.0 | 57.0 |

| 1 | 159.3 | 54.4 |

| 2 | 169.4 | 57.8 |

| 3 | 181.4 | 61.9 |

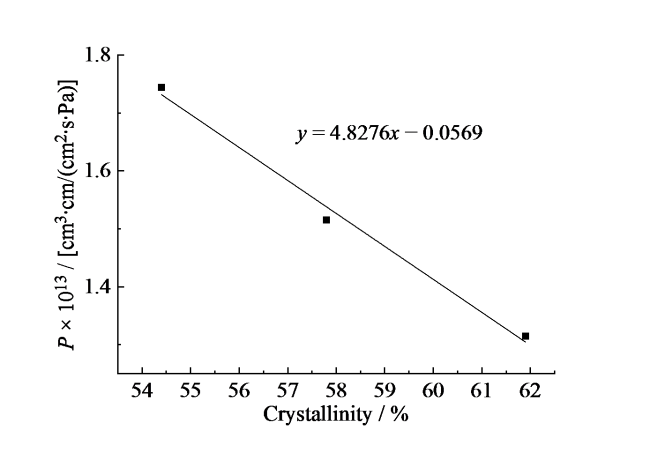

2.2 结晶度对氢渗透特性的影响

Table 2 Hydrogen permeation test results of HDPE表2 HDPE氢气渗透测试结果 |

| Sample | Crystallinity / % | P / [cm3∙cm/(cm2∙s∙Pa)] | D / (cm2/s) | S / [cm3/(cm2∙s∙cm∙Hg)] |

|---|---|---|---|---|

| 1 | 54.4 | 1.744 × 10-13 | 1.962 × 10-6 | 1.185 × 10-4 |

| 2 | 57.8 | 1.515 × 10-13 | 1.538 × 10-6 | 1.313 × 10-4 |

| 3 | 61.9 | 1.315 × 10-13 | 1.301 × 10-6 | 7.580 × 10-3 |

Fig. 3 Fitting curve between gas permeability coefficient and crystallinity图3 气体渗透系数与HDPE结晶度的拟合曲线 |

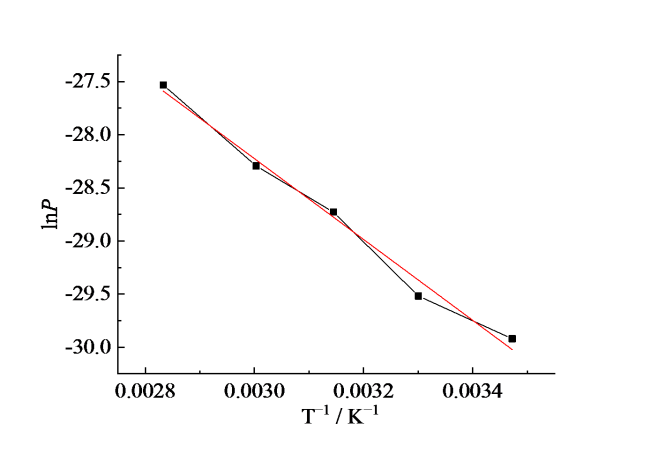

2.3 温度对氢渗透的影响

Table 3 Hydrogen permeability of sample 2 at different temperatures表3 不同温度下试样2的氢渗透性能 |

| Temperature / oC | P / [cm3∙cm/(cm2∙s∙Pa)] | D / (cm2/s) | S / [cm3/(cm2∙s∙cm∙Hg)] |

|---|---|---|---|

| 15 | 1.014 × 10-13 | 1.407 × 10-6 | 9.617 × 10-5 |

| 30 | 1.515 × 10-13 | 1.538 × 10-6 | 1.313 × 10-4 |

| 45 | 3.336 × 10-13 | 3.280 × 10-6 | 1.352 × 10-4 |

| 60 | 5.156 × 10-13 | 5.761 × 10-6 | 1.191 × 10-4 |

| 80 | 1.104 × 10-12 | 8.642 × 10-6 | 1.705 × 10-4 |

Fig. 4 Hydrogen permeability coefficient at different temperatures and the fitting curve图4 不同温度氢气渗透系数及拟合曲线 |