0 引言

1 实验部分

1.1 材料与设备

1.2 磷/碳复合负极的制备

1.3 固态电解质的制备

1.4 材料结构表征

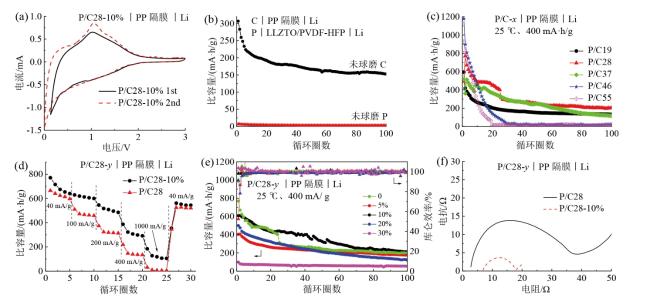

2 结果与讨论

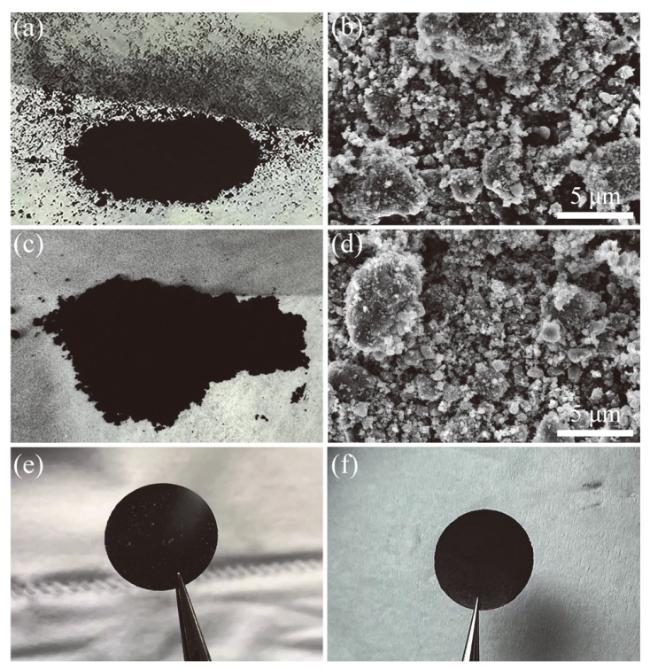

图1 球磨后复合粉末的照片:P/C的光学照片(a)和SEM图(b);P/C28-10%的光学照片(c)和SEM图(d);P/C(e)和P/C28-10%(f)压在镍网上的光学照片Fig.1 Images of the composite powder after ball milling: optical (a) and SEM (b) images of P/C; optical (c) and SEM (d) images of P/C28-10%; optical images of P/C (e) and P/C28-10% (f) pressed on a nickel mesh |

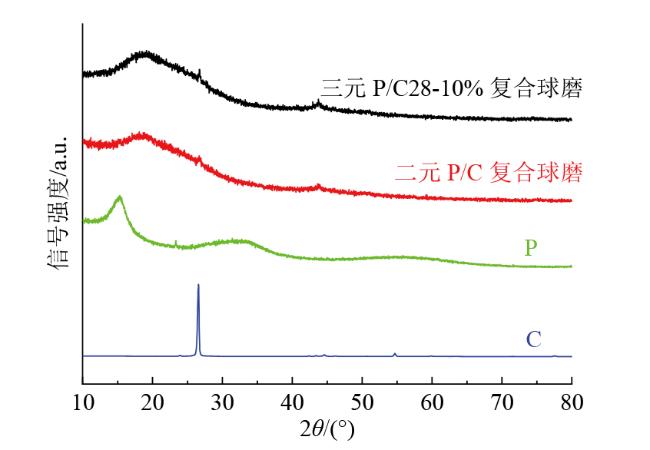

图3 (a)P/C/Li丨PP隔膜丨Li半电池的CV曲线;(b)C丨PP隔膜丨Li、P丨LLZTO/PVDF-HFP丨Li电池循环性能曲线;(c)P/C-x丨PP隔膜丨Li电池循环性能曲线;P/C28-y丨PP隔膜丨Li电池的倍率性能曲线(d)、循环性能曲线(e)和EIS曲线(f)Fig.3 (a) CV curves for P/C/Li | PP membrane | Li half-cell; (b) cycling performance curves for C | PP membrane | Li, P | LLZTO/PVDF-HFP | Li battery; (c) cycling performance curves for P/C-x | PP membrane | Li battery; rate performance curves (d), cycling performance curves (e), and EIS curves (f) for P/C28-y | PP membrane | Li battery |

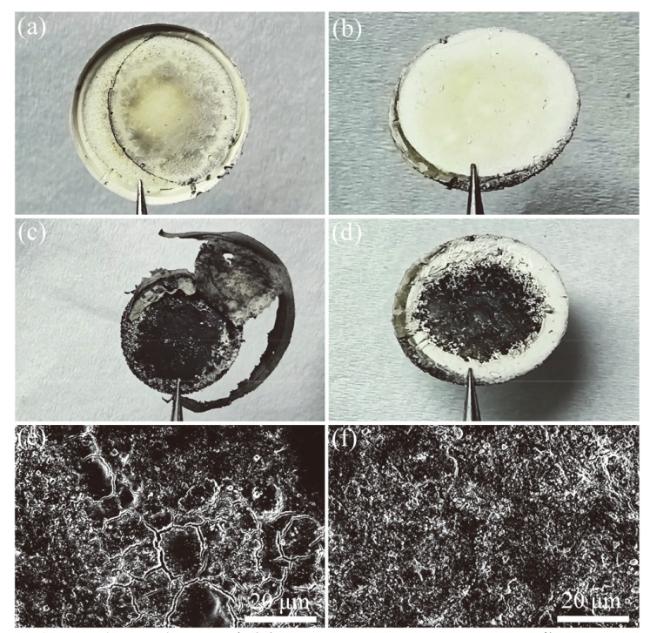

图4 (a、c)100次循环后LLZTO/PVDF-HFP膜和二元P/C28复合粉末光学照片;(b、d)100次循环后LLZTO/PVDF-HFP膜和三元P/C28-10%复合粉末光学照片;(e)100次循环后P/C28复合粉末SEM图;(f)100次循环后三元P/C28-10%复合粉末SEM图Fig.4 (a, c) Optical photos of LLZTO/PVDF-HFP film and binary P/C28 composite powder after 100 cycles; (b, d) optical photos of LLZTO/PVDF-HFP film and ternary P/C28-10% composite powder after 100 cycles; (e) SEM image of P/C28 composite powder after 100 cycles; (f) SEM image of ternary P/C28-10% composite powder after 100 cycles |

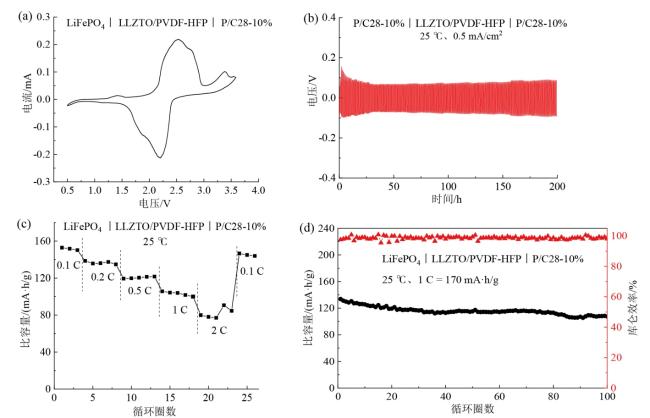

图5 (a)LiFePO4丨LLZTO/PVDF-HFP丨P/C28-10%全电池的CV曲线;(b)P/C28-10%丨LLZTO/PVDF-HFP丨P/C28-10%对称电池的锂沉积/剥离循环测试;LiFePO4丨LLZTO/PVDF-HFP丨P/C28-10%电池的倍率性能曲线(c)和循环性能曲线(d)Fig.5 (a) CV curve of LiFePO4 | LLZTO/PVDF-HFP | P/C28-10% full cell; (b) lithium deposition/stripping cycle testing of P/C28-10% | LLZTO/PVDF-HFP | P/C28-10% symmetric batteries; rate performance curve (c) and cycle performance curve (d) of LiFePO4 | LLZTO/PVDF-HFP | P/C28-10% battery |