ISSN 2095-560X

CN 44-1698/TK

CONDEN XJIIA8

CN 44-1698/TK

CONDEN XJIIA8

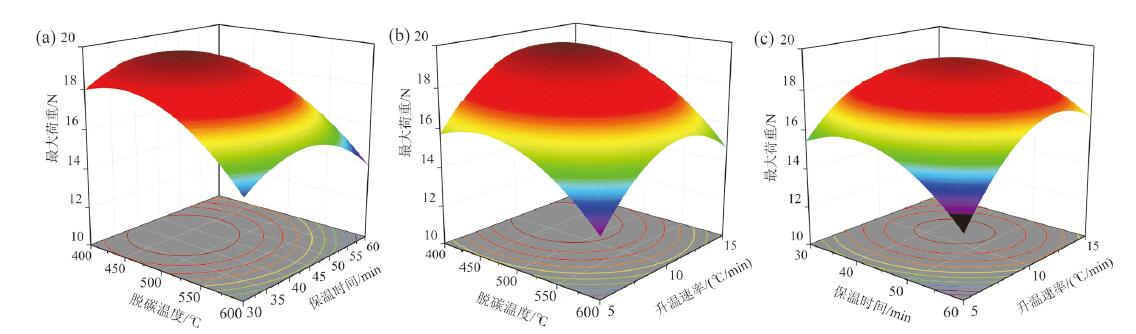

Fig. 6 The response surface diagram of the effects of different factors on the maximum load of recovered fibers: (a) the effect of decarburization temperature and holding time on the maximum load; (b) the effect of decarburization temperature and heating rate on the maximum load; (c) the influence of holding time and heating rate on the maximum load

Fig. 6 The response surface diagram of the effects of different factors on the maximum load of recovered fibers: (a) the effect of decarburization temperature and holding time on the maximum load; (b) the effect of decarburization temperature and heating rate on the maximum load; (c) the influence of holding time and heating rate on the maximum load